This website uses cookies to provide you with the best possible service. The cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site are most interesting and useful to you.

WK04 Weigher

26 June 2018

Packing line for potatoes

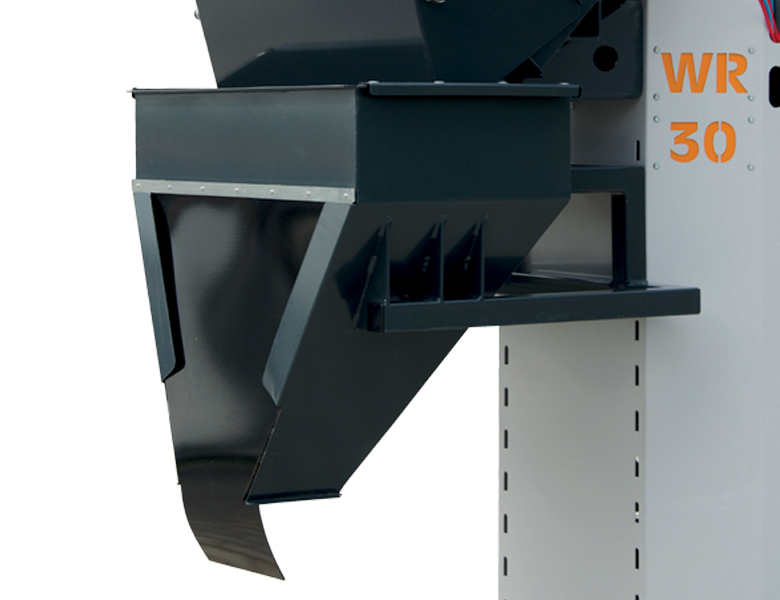

5 April 2017WR30 Industrial Weigher: Precision Weighing for Potatoes & Vegetables

Achieve unparalleled accuracy and efficiency in your packing line with the KMK WR30, a compact and robust machine engineered for precise weighing and portioning of potatoes, onions, and other vegetables. Designed for versatility, the WR30 seamlessly handles portions from 2.5 kg to 50 kg, making it the perfect solution for operations of any scale.

At the heart of the WR30 are its high-performance transport belts. Depending on the model, the machine features single or dual belts (one wide, one narrow) for a two-stage dosing process. This, combined with fully adjustable belt speeds, gives you complete control to achieve perfect portion accuracy, minimize product giveaway, and maximize your profits.

Key Benefits:

-

Unmatched Precision: Advanced dosing system ensures consistent, accurate weights for every single portion.

-

Flexible Operation: Switch effortlessly between fully automatic mode (integrated with a packing machine) and manual mode with a convenient foot switch.

-

Intuitive Control: The user-friendly Mitsubishi HMI display makes setup and operation simple, reducing training time and minimizing operator error.

-

Built to Last: Constructed from heavy-duty, powder-painted steel, the WR30 is designed to withstand the demanding environment of any packing house, ensuring a long-term return on your investment.

Whether you are upgrading your existing line or building a new one, the WR30 Weigher provides the reliability and precision your business needs to thrive.

OPTIONAL EQUIPMENT:

- weighing meter with legal approval

- weighing container up to 50 kg of vegetables

- belt adjusted for carrot/parsley

- acid resistant stainless steel construction

- conveyor belt for packing machine

- product sensor in the receiving hopper

- intake hopper’s divider

- additional chutes for different bags

| TECHNICAL DATA | |||||

| WR-30-MINI | WR-30-MIDI | WR-30 | WR-50 | WR-50-MAXI | |

| Weighing container | 30 kg | 30 kg /50 kg | 30 kg /50 kg | 50 kg | 50 kg |

| Weighing scope | 2,5 kg - 30 kg | 2,5 kg - 30 kg (optionally 50 kg) |

2,5 kg - 30 kg (optionally 50 kg) |

5 kg - 50 kg | 5 kg - 50 kg |

| Max. capacity | 4 t/h* | 5,5 t/h* | 5,5 t/h* | 8 t/h* | 8 t/h* |

| Main belt width | 380 mm | 380 mm | 380 mm | 500 mm | 500 mm |

| Narrow belt width | - | 85 mm | 85 mm | 100 mm | 100 mm |

| Work with packing machine | - | - | up to 25 kg bags | up to 50 kg bags | up to 50 kg bags |

| Touch system | 4,3” | 4,3” | 7” | 7” | 7” |

| Electrical supply | 230 V | 400 V | 400 V | 400 V | 400 V |

| Pneumatical supply | 6 bar 35 l/min | 6 bar 50 l/min | 6 bar 50 l/min | 6 bar 50 l/min | 6 bar 50 l/min |

| Power consumption | 1,8 kW | 2 kW | 2 kW | 2 kW | 2 kW |

| Dimensions | 3,0 x 1,0 x 2,2 m | 3,0 x 1,2 x 2,2 m | 3,3 x 1,2 x 2,5 m | 3,3 x 1,2 x 2,5 m | 3,6 x 1,2 x 2,8 m |

| Net weight | 330 kg | 380 kg | 440 kg | 445 kg | 480 kg |

*Capacity depends on the size of the batches.