This website uses cookies to provide you with the best possible service. The cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site are most interesting and useful to you.

P Stationary conveyor belts

27 June 2018

ZB Dosing bunkers

27 June 2018BM Modular Bunker: The Scalable Heart of Your Production Line

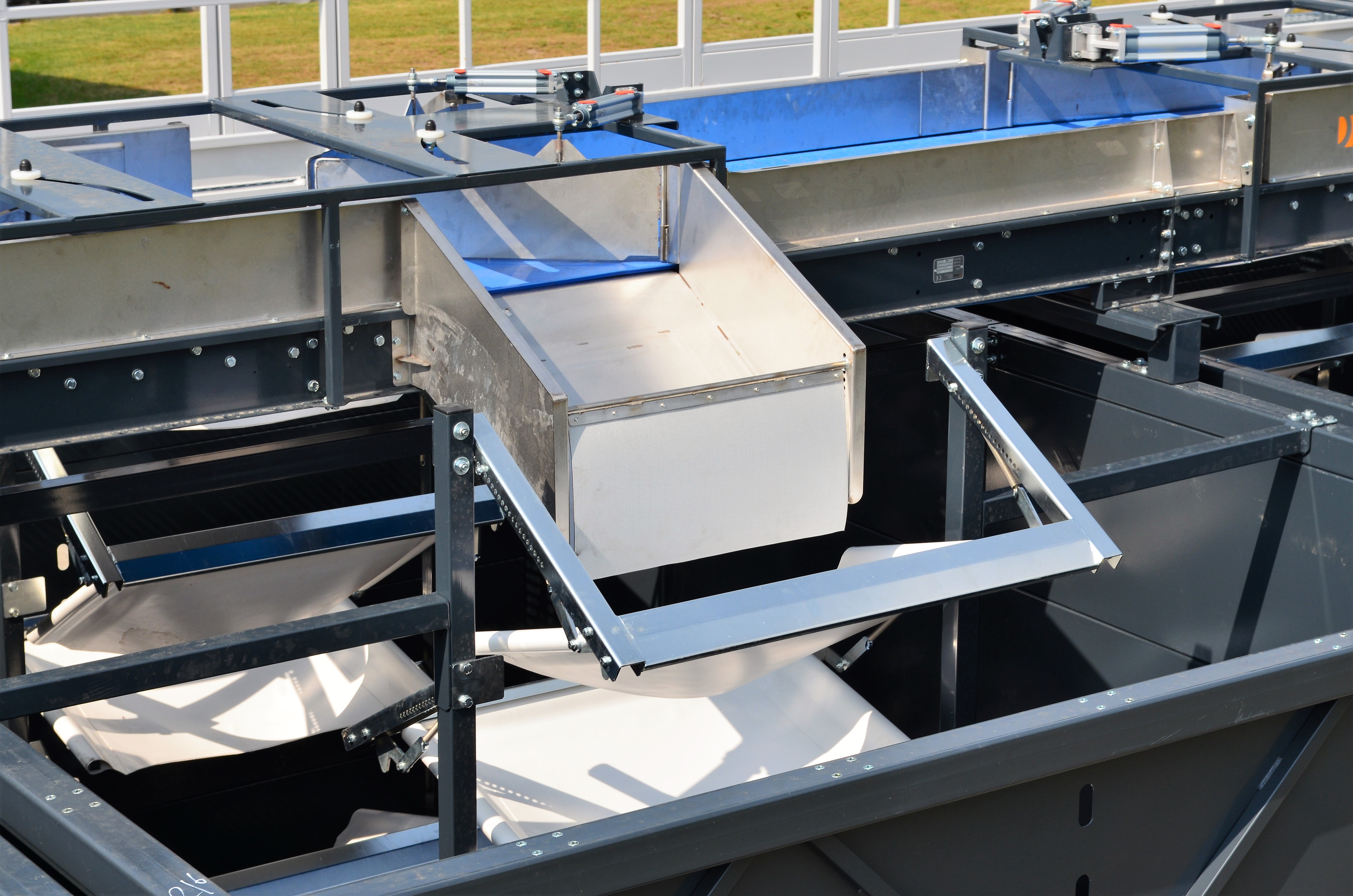

Create a smooth, continuous, and efficient workflow with the KMK BM Modular Bunker. This versatile machine is designed to be the central hub of your line, providing essential product buffering to absorb surges from intake, and then delivering a precise, even flow of product to your downstream equipment.

A Fully Modular and Scalable Design

The BM Bunker is engineered to grow with your business. The system consists of a robust base unit with the option to add 0.5-meter-high sidewall sections. This modularity allows you to configure the exact capacity you need now, with the freedom to easily expand in the future. It’s a cost-effective and future-proof investment for any growing operation.

Gentle Handling and Precision Dosing

Every aspect of the BM Bunker is designed to protect your product and optimize your line’s performance.

-

Precise Flow Control: The unloading conveyor belt at the bottom of the bunker is equipped with an inverter for stepless speed adjustment, guaranteeing a perfectly consistent feed to your sorting and packing machines.

-

Gentle on Your Product: The inner walls of the bunker base and the adjustable, roof-shaped cover above the belt are lined with a special shock-absorbing material. This minimizes bruising and damage as the product is loaded and buffered.

-

Overload Protection: The adjustable roof-shaped cover prevents the conveyor belt from being overwhelmed, ensuring a manageable flow and reducing strain on the drive system.

-

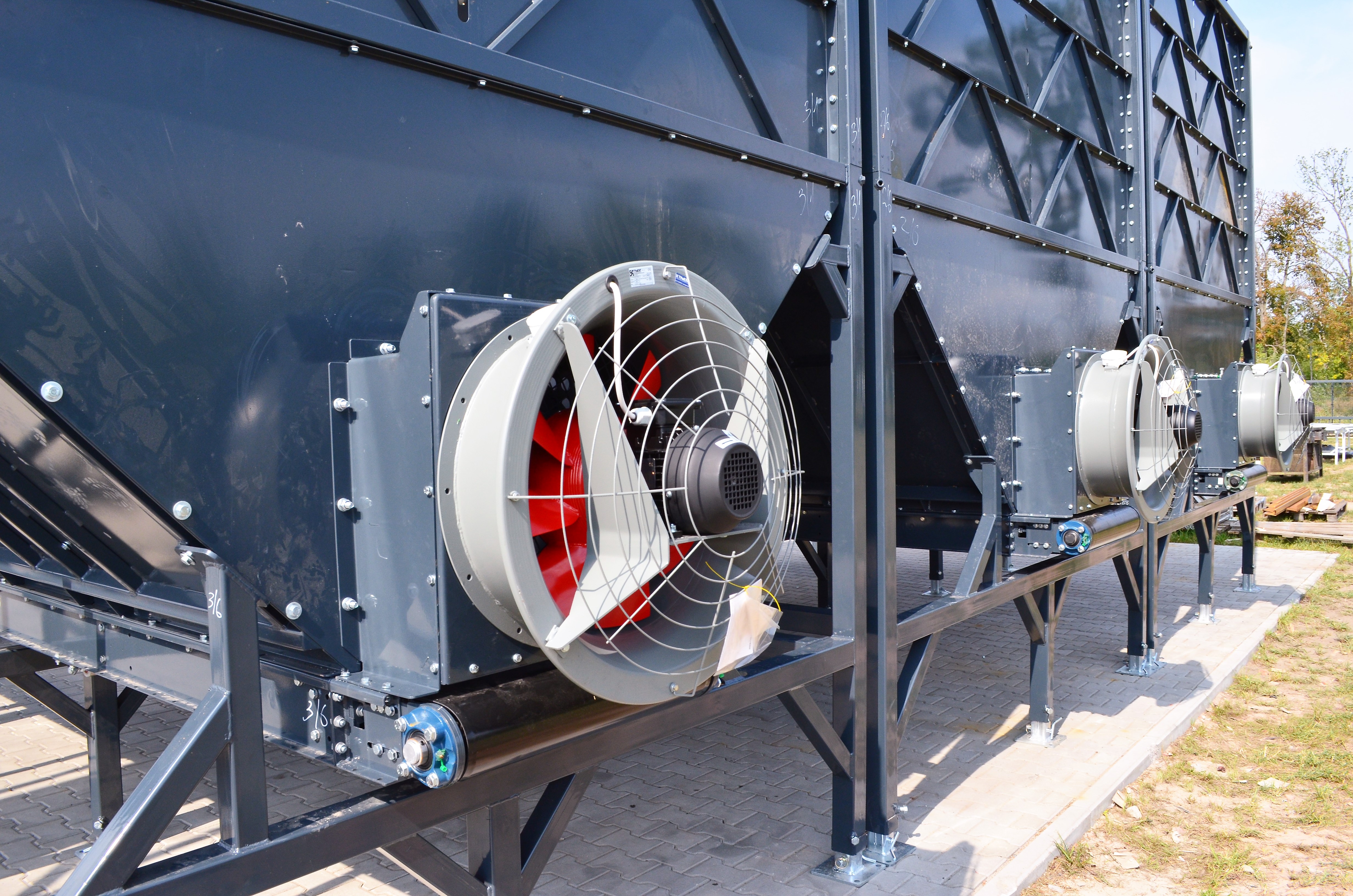

Optional Ventilation: For sensitive products like potatoes, the bunker can be equipped with a ventilator and a sealed shutter system, providing effective aeration to maintain product quality during buffering.

-

Durable Construction: Built with a heavy-duty, powder-painted steel frame, the BM Bunker is designed for years of reliable service.

Position the BM Modular Bunker at any point in your line to eliminate bottlenecks and create a seamless, highly efficient production process.

| TECHNICAL DATA | |

| BM | |

| Available width | 1,5 m-3,0 m |

| Available lenght | 1,5 m-10,0 m |

| Capacity | from 1 m³ to 60 m³ (0,6 t - 36 t potatoes) |

| Belt type | PVC belt |

| Belt working width | 0,4 m or 0,6 m |

| Electrical supply | 400 V |

OPTIONAL EQUIPMENT:

- all stainless acid-resistant steel construction

- extra-durability shock-absorbing material

- additional 3-side top wall

- extended belt speed adjustment range

- product sensor (for belt work in START-STOP mode)

- ventilator

- fixed fall-damper

- inverter with a sensor that controls the speed of an unloading belt

- product level sensor

- ladder or platform

- adjustment to central control cabinet