This website uses cookies to provide you with the best possible service. The cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site are most interesting and useful to you.

APB Packing machine

18 April 2025

Semi-automatic bag sealing machine SAB

23 March 2023Box tipper WSD

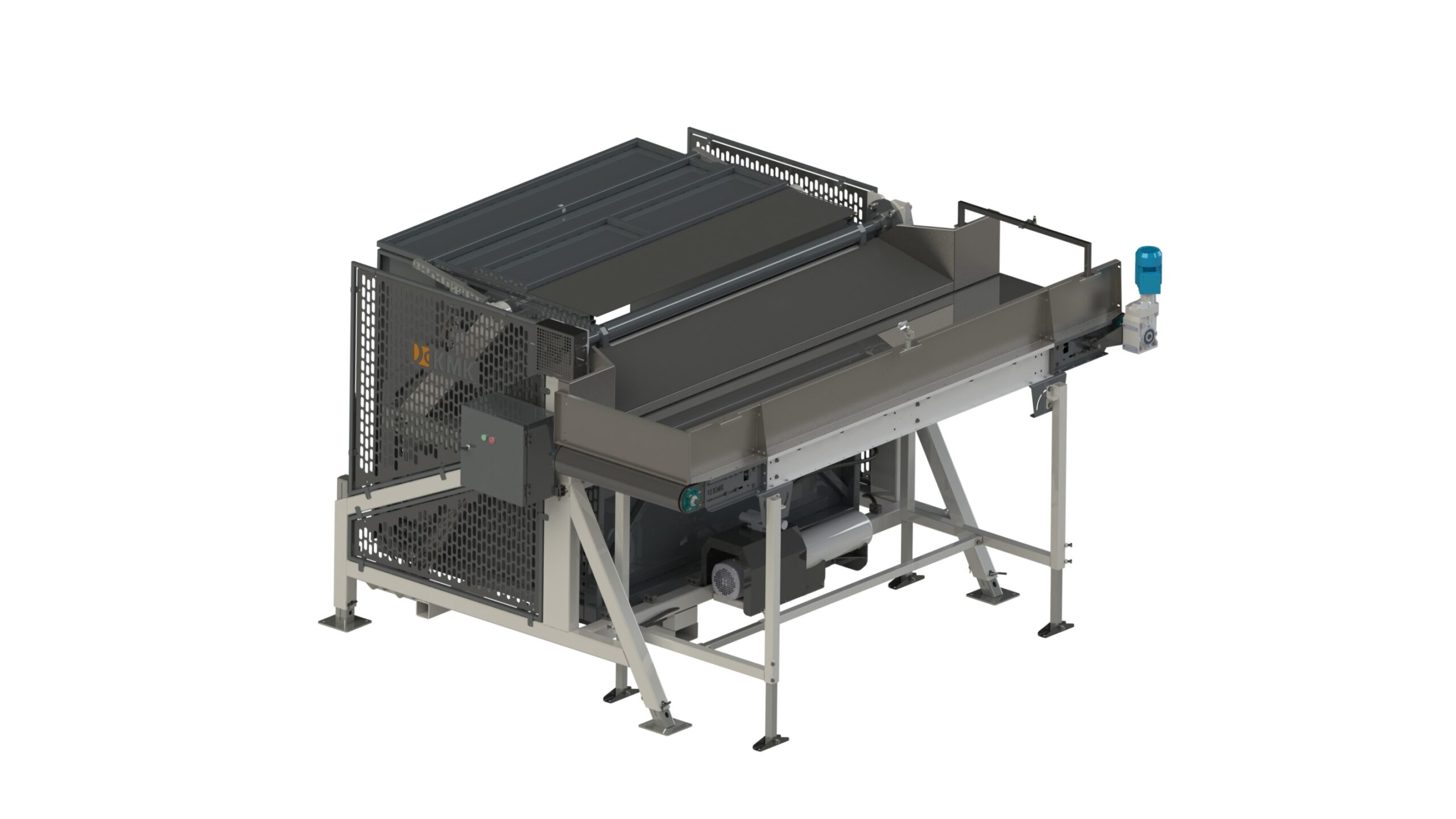

WSD Box tipper is a device designed for emptying boxes with vegetables, which thanks to its equipment can act as a dispenser.

As standard the WSD box tipper is equipped with hydraulically driven box cover, advanced control system and unloading conveyor.

Two types of unloading conveyors are available: longitudinal and crosswise.

The operator sets the desired dosing capacity on the touch panel. As a result working elements of the machine operate in such a way as to obtain this set capacity. The ultrasonic sensor, which measures the level on product discharged on the belt, controls the tipping of the box. Another sensor mounted further on on the unloading conveyor controls the level of conveying goods on the belt and makes the machine automatically adjust the speed of the belt to the set capacity. The applied solutions allow for even and accurate dosing of goods to subsequent machines in the line.

Thanks to the special tipping mechanism and equipping the machine with two double-acting cylinders, the maximum tipping angle of the tipper’s platform is 180 °.

Thanks to the radio remote control, the operator can operate the machine without leaving the forklift.

Regardless of equipment variant, WS tipper is available in different sizes: suitable for boxes with width from 1400 mm up to 2400 mm.

As standard, the machine is made of powder coated steel.

| Technical data: | ||||||

| WSD-14 | WSD-16 | WSD-18 | WSD-20 | WSD-22 | WSD-24 | |

| Max. box width | 1,4 m | 1,6 m | 1,8 m | 2,0 m | 2,2 m | 2,4 m |

| Max. box height | 1,3 m | |||||

| Max. tipping angle | 180° | |||||

| Electrical supply | 400 V | |||||

| Power consumption | 3,5 kW | |||||

Optional equipment:

- Adjustment to central control cabinet