This website uses cookies to provide you with the best possible service. The cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site are most interesting and useful to you.

SZR Separator

1 July 2022

TR Selection tables

1 July 2022JC HEDGEHOG

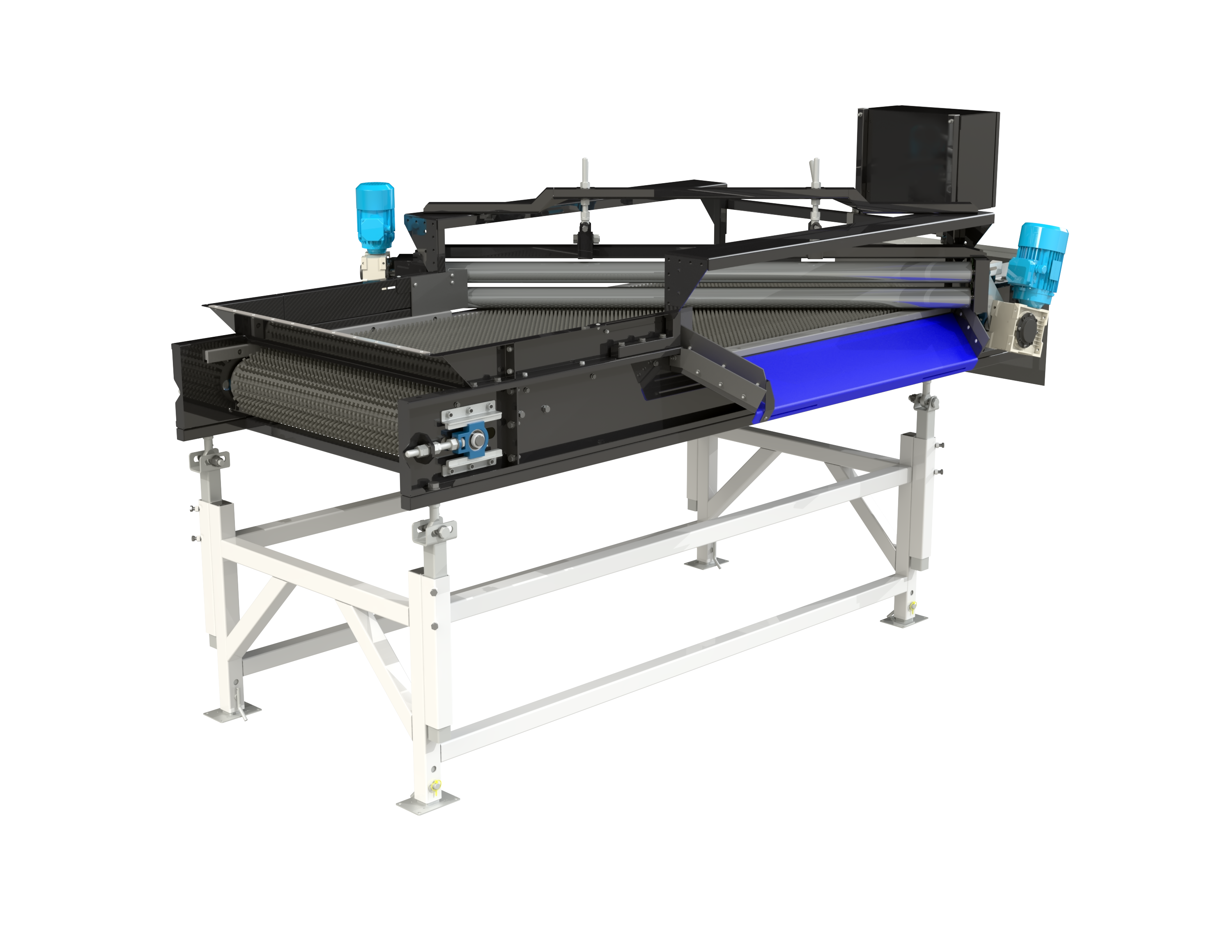

JC Hedgehog: The Ultimate Pre-Cleaner for Soil, Clod, and Haulm Removal

Start your packing process with the cleanest possible crop. The KMK JC Hedgehog is a professional-grade pre-cleaner, expertly designed to be the first line of defense against field contamination. It aggressively yet gently separates potatoes from clods of soil, stones, haulm (vines), and other debris, ensuring that only your core product moves on to the next stage.

By implementing the JC Hedgehog at the start of your receiving line, you not only improve the efficiency of your entire operation but also protect your downstream equipment—like sorters, washers, and weighers—from unnecessary wear and tear.

Powerful Dual-Action Cleaning

The JC Hedgehog utilizes a highly effective two-stage cleaning process:

-

Pintle Belt Separation: Dirty potatoes are fed onto a wide belt of durable rubber pintles. The potatoes are carried along the top of the pintles, while smaller clods, loose soil, and stones fall through and are discharged onto a central waste conveyor.

-

Active Haulm Removal: Above the belt, a set of two active, acid-resistant steel rollers works to detangle and pull any remaining haulm or vines from the product flow, directing them efficiently towards the waste chute.

Unmatched Adjustability for All Field Conditions

Harvest conditions are never the same. That's why the JC Hedgehog is engineered for maximum adjustability. The machine’s entire working angle can be adjusted in three dimensions, while the active rollers have their own two-dimensional angle adjustment. This unprecedented level of control allows you to fine-tune the machine’s performance to perfectly match any condition, from wet, sticky soil to dry, clumpy dirt.

Key Features & Benefits:

-

Boosts Line Efficiency: Delivers a cleaner product to the rest of your line, improving the accuracy and performance of all subsequent equipment.

-

Total Cleaning Control: Independent, adjustable speeds for the pintle belt and active rollers allow you to dial in the perfect cleaning intensity.

-

Flexible Layout: Clean potatoes can be discharged from chutes on either the left or right side of the machine to fit your line's layout.

-

Durable Construction: Built with a heavy-duty, powder-painted steel frame to withstand the most demanding intake conditions.

| TECHNICAL DATA | |||

| JC-20 | JC-25 | JC-30 | |

| Working width | 1,0 m | 1,0 m | 1,0 m |

| Working length | 2,0 m | 2,5 m | 3,0 m |

| Electrical supply | 400 V | 400 V | 400 V |

| Power consumption | 3,0 kW | 3,0 kW | 3,0 kW |