This website uses cookies to provide you with the best possible service. The cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site are most interesting and useful to you.

NSP Box filler

22 April 2025

APB Packing machine

18 April 2025Receiving bunker BP

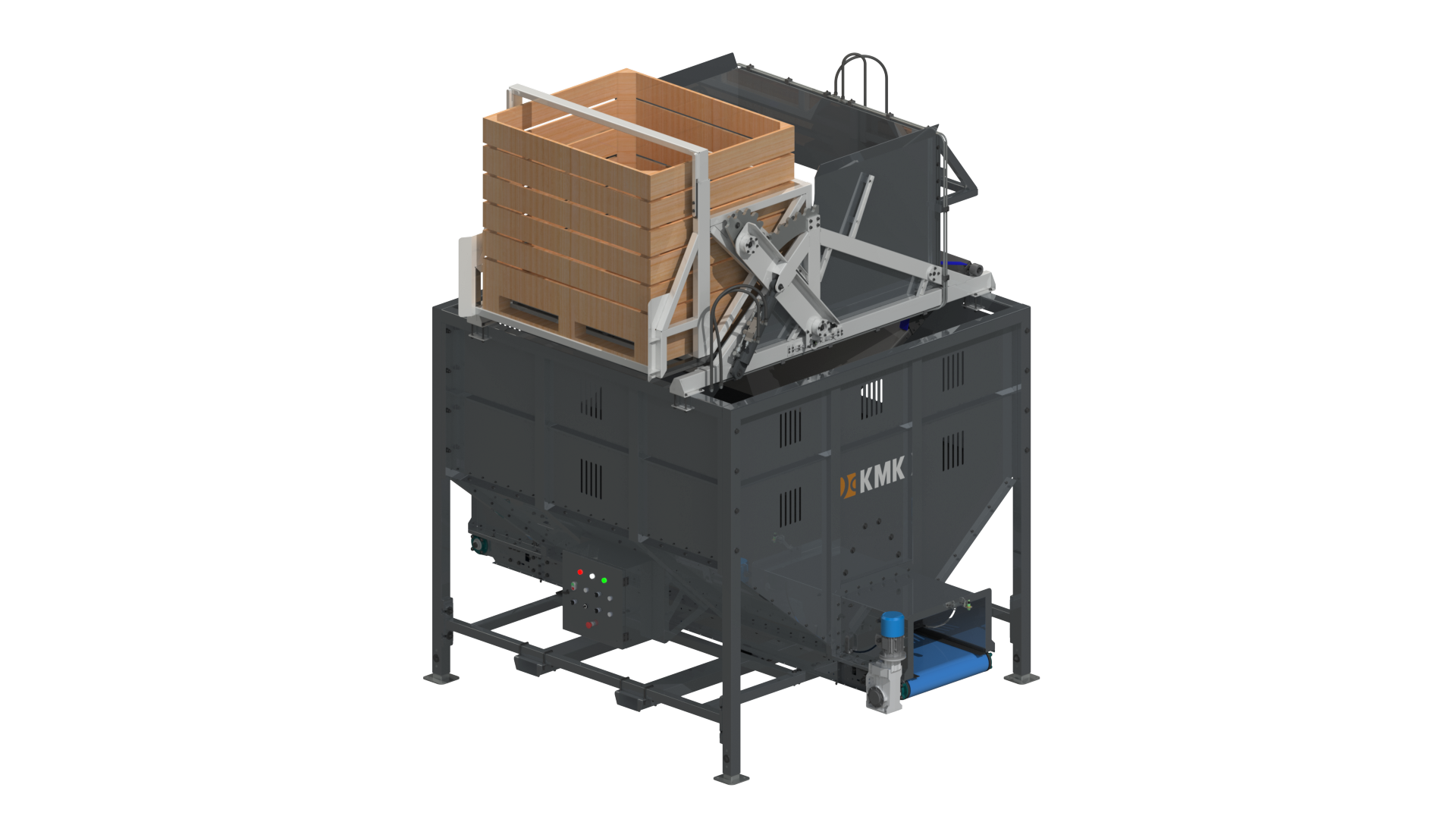

BP Receiving Bunker: The All-in-One Intake Powerhouse

Simplify and streamline the start of your production line with the KMK BP Receiving Bunker, a comprehensive and compact system that combines a high-capacity receiving hopper and an integrated box tipper into a single, efficient unit. This all-in-one design saves significant floor space, reduces equipment complexity, and provides a powerful, centralized solution for both unloading and dosing your product.

High-Capacity Intake and Unmatched Flexibility

With a generous 7.6 m³ capacity, the BP Receiving Bunker can easily absorb large volumes of produce, ensuring a continuous buffer for your line. The integrated hydraulic tipper is a high-performance unit, capable of a full tip-and-return cycle in just 30 seconds, allowing for a maximum throughput of approximately 35 boxes per hour.

What truly sets the BP bunker apart is its flexibility:

-

Configurable Layout: The integrated box tipper can be mounted on any side of the bunker, allowing you to configure the machine to perfectly match your facility's layout and workflow.

-

Remote Control Operation: A standard radio remote control allows the forklift operator to manage the entire tipping process safely and efficiently without ever leaving their cab.

-

Mobile Design: The entire unit is equipped with forklift handles, making this high-capacity bunker surprisingly mobile. You can easily transport and reposition the machine as your operational needs change.

An advanced control system manages both the tipping cycle and the bunker's fill level, while the unloading belt conveyor at the base provides a steady, controlled flow of product to the next stage of your line.

| Technical data | ||||

| ВР-14 | ВР-16 | ВР-18 | ||

| Max. box width | 1,4 m | 1,6 m | 1,8 m | |

| Max. box height | 1,3 m | |||

| Max. tipping angle | 180 ° | |||

| Capacity | 7,6 m3 (3,5 t) | |||

| Electrical supply | 400 V | |||

| Power consumption | 3,5 kw | |||

Optional equipment:

- electric motor of the unloading conveyor mounted in the middle of its length

- product sensor (for belt work in START-STOP mode)