This website uses cookies to provide you with the best possible service. The cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site are most interesting and useful to you.

BM Modular bunkers

27 June 2018

NS Box filler

27 June 2018ZB Dosing Bunker: The Versatile Receiving Hopper for Boxes and Big-Bags

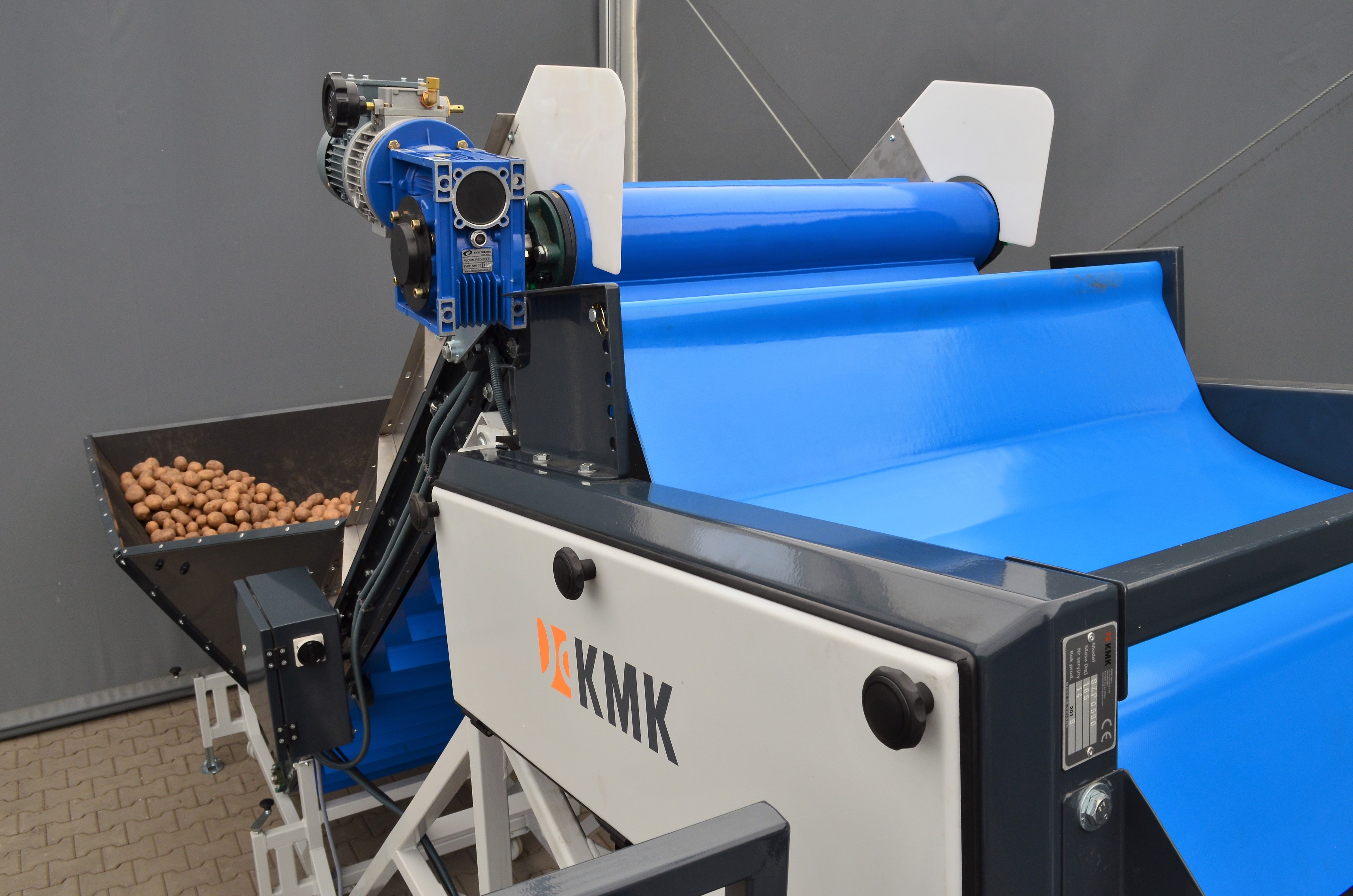

Provide a steady, controlled start to your processing line with the KMK ZB Dosing Bunker. This robust device is designed as a versatile receiving hopper, capable of efficiently unloading both standard vegetable boxes and large-capacity big-bags. Its primary role is to buffer your product and then deliver a consistent, even flow to the next stage of your line, preventing bottlenecks and maximizing efficiency.

Precise Dosing and Customizable Design

The ZB Bunker ensures a perfectly managed outflow of produce. A durable conveyor belt at the base of the hopper, protected from overloading by a roof-shaped cover, moves the product forward. With stepless speed adjustment via an inverter, you can precisely control the dosing rate to perfectly match the capacity of your downstream equipment. To suit different product types, you can choose between a smooth PVC belt or a heavy-duty bar belt.

Upgrade with an Integrated Soil Separator

Transform the ZB Bunker into a powerful 2-in-1 machine with the optional soil separator. This integrated module pre-cleans your vegetables as they are discharged, effectively removing loose soil, clods, and other minor field contamination. This saves valuable floor space and investment costs by combining two critical processes into a single unit.

Key Features & Benefits:

-

Versatile Intake: Expertly handles produce from both standard boxes and big-bags.

-

Optional Pre-Cleaning: Add the soil separator module to clean and dose in one step.

-

Consistent Product Flow: The variable-speed unloading conveyor provides a smooth and even feed, optimizing the performance of your entire line.

-

Customizable Belt Options: Choose between a PVC or bar belt to best suit your product.

-

Durable Construction: Built with a heavy-duty, powder-painted steel frame, the ZB Dosing Bunker is designed for years of reliable operation.

| TECHNICAL DATA | ||||

| ZB-II-250/70 | ZB-II-300/70 | ZB-II-350/70 | ZB-II-400/70 | |

| Belt type | PCV/bar belt | |||

| Belt width | 0,7 m | |||

| Belt lenght | 2,5 m | 3,0 m | 3,5 m | 4,0 m |

| Theoretical capacity | 1,2 m³ | |||

| Max. outlet height | 1850 mm | 2175 mm | 2495 mm | 2800 mm |

| Electrical supply | 400 V | |||

| TECHNICAL DATA | ||||

| ZB-II-250/70 | ZB-II-400/90 | |||

| Belt type | PCV/bar belt | |||

| Belt width | 0,7 m | 0,9 m | ||

| Belt lenght | 2,5 m | 4,0 m | ||

| Theoretical capacity | 1,5 m³ | 3,0 m³ | ||

| Max. outlet height | 1200 mm | 1500 mm | ||

| Electrical supply | 400 V | |||

OPTIONAL EQUIPMENT:

- stainless steel construction

- capacity sensor

- inverter for additional speed adjustment

- clod separator with an inverter

- heavy duty soft-landing

- product sensor

- adjustment to central control cabinet