This website uses cookies to provide you with the best possible service. The cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site are most interesting and useful to you.

Grader SR

2 March 2023

Sorting and packaging line in Austria

4 July 2022R1/R2 Packing Machines

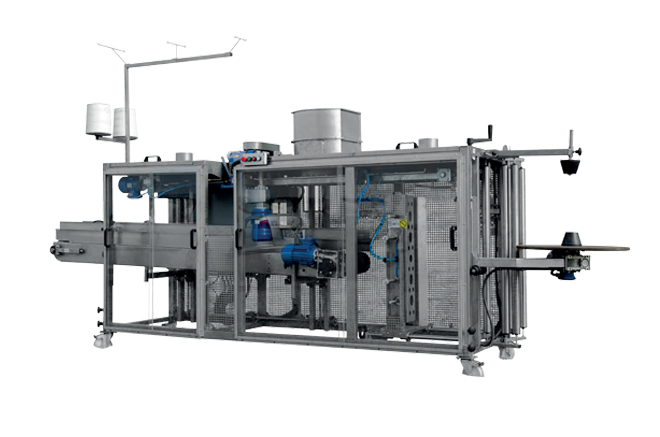

R1 & R2 Automatic Mesh Bagging Machines: Fast, Reliable, and Professional Packing

Transform your vegetable packing process with the KMK R1 and R2, a series of robust machines engineered to automatically pack potatoes, onions, carrots, and other root vegetables into mesh bags. Designed for high-output operations, these machines automate the entire workflow—from cutting bags off the roll to filling and sewing them shut—dramatically increasing your speed, reducing labor costs, and delivering a consistent, professional product every time.

The R-series is designed to handle a versatile weight range from 2.5 kg to 25 kg and integrates seamlessly with KMK weighers (WK and WR30 series) to create a fully synchronized packing line.

Choose Your Perfect Closure: R1 vs. R2

While both models deliver exceptional performance, the key difference lies in the sewing head, allowing you to choose the perfect finish for your market needs.

-

R2 Packing Machine: Equipped with a premium double-thread Fischbein F100 sewing head. This provides a stronger, more secure closure that prevents unraveling and offers a superior, professional look ideal for retail and export markets.

-

R1 Packing Machine: Features a reliable single-thread Fischbein/Newlong sewing head, offering a standard, cost-effective closure perfect for high-volume, general-purpose packing.

Smart Features for Uninterrupted Operation:

-

Jam Prevention System: An ultrasonic sensor on the intake hopper constantly monitors product flow, preventing accidental jams and costly downtime.

-

Durable Construction: Built with a heavy-duty, powder-painted steel frame, the R-series is made to endure the rigors of a busy packing environment.

-

Intuitive Controls: A user-friendly Mitsubishi display provides simple and intuitive control over all machine operations.

Optional Upgrades for Perfect Bag Presentation: For challenging products like carrots, enhance your machine with an intake hopper vibration engine for smoother product flow and a conveyor belt vibration engine that gently settles vegetables for a perfectly uniform and appealing final bag.

| TECHNICAL DATA | ||

| R1 | R2 | |

| Sewing head | New Long NP-7A/Fischbein F | Fischbein F100 |

| Packing scope | 2,5 kg - 25 kg | 2,5 kg - 25 kg |

| Control system | PLC Mitsubishi | PLC Mitsubishi |

| Touch screen | 4,3” | 4,3” |

| Electrical supply | 400 V | 400 V |

| Pneumatical supply | 6 bar 30 l/min | 6 bar 30 l/min |

| Power consumption | 3,2 kW | 3,2 kW |

| Dimensions | 4,4 m x 1,0 m x 2,2 m | 4,4 m x 1,0 m x 2,2 m |

| Net weight | 600 kg | 630 kg |

OPTIONAL EQUIPMENT:

- acid-resistant stainless steel cosntruction

- intake hopper vibrations engine

- belt vibration engine

- intake hopper reducer

- thermal transfer printer

- ventilators for exhaust fumes

- potatoes passports feeder

- set of sensors for automatic palletzing