This website uses cookies to provide you with the best possible service. The cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site are most interesting and useful to you.

BP Receiving bunker

18 April 2025

WSD Box tipper

18 April 2025Packing machine APB

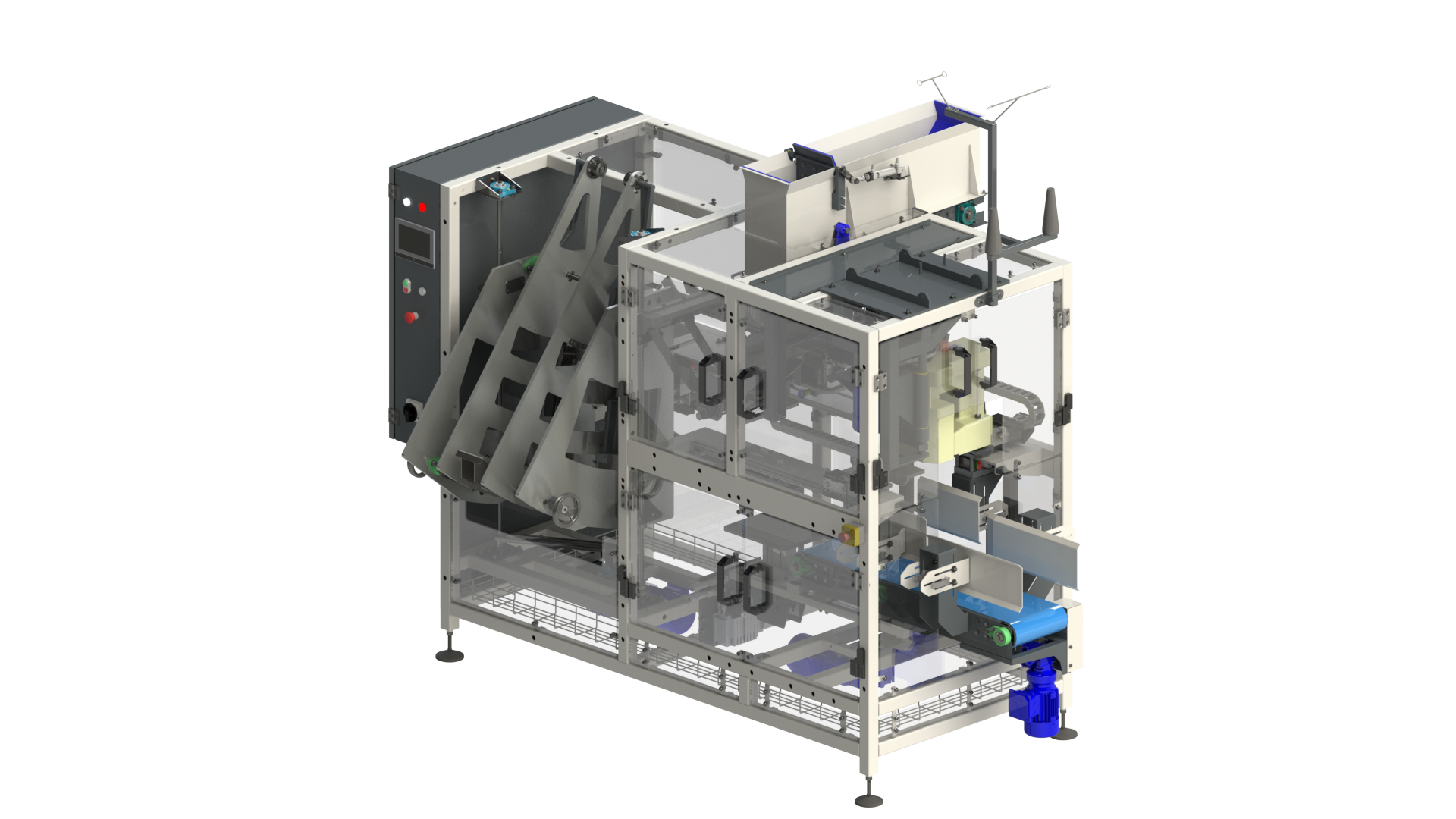

APB is a fully automatic device for packing potatoes into paper bags ranging from 2 kg to 10 kg.

The machine takes an empty paper bag from the bag feeder, moves it underneath the infeed hopper, fills it with a weighed out portion of vegetables and sews it up.

The crops fall onto a conveyor with shock-absorbing belt. At the same time, the conveyor serves as a buffer for a single batch, which optimizes the efficiency of the device. A sensor mounted on the infeed hopper controls its throughput, preventing disruptions in machine’s run caused by an accidental blocking of products in the hopper. Mounting a sewing head on a swinging arm allows comfortable access to it when inserting the thread.

Getting the machine ready to work with various packages is optimized thanks to the possibility of creating recipes in the machine‘s software with different settings for different packages. The height adjustment of the basic working elements is electrically driven and different positions can be stored in the machine’s software. The device is operated by means of a large, user-friendly Mitsubishi touch screen. Additional adjustments are made with the help of handles. Those adjustments‘ values are displayed on clear digital position

indicators, which significantly facilitates getting the machine ready to work with bags of other dimensions.

APB packing machine is adjusted to work with WK weighers. As a standard, the construction of the machine is made of powdercoated steel.

| Technical data | ||

| APB-1 | APB-2 | |

| Sewing head | New Long NP-7A / Fischbein F | Fischbein F100 / New Long DS-9C |

| Packing scope | 2 kg - 10 kg | 2 kg - 10 kg |

| Max. capacity | 12 worków /min | 12 worków /min |

| Bag feeder capacity | 200 worków | 200 worków |

| Touch screen | 7” | 7” |

| Electrical supply | 400 V | 400 V |

| Power consumption | 3,0 kW | 3,0 kW |

Optional equipment:

- All stainless construction