This website uses cookies to provide you with the best possible service. The cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team understand which sections of the site are most interesting and useful to you.

APB Packing machine

18 April 2025

Semi-automatic bag sealing machine SAB

23 March 2023Box tipper WSD

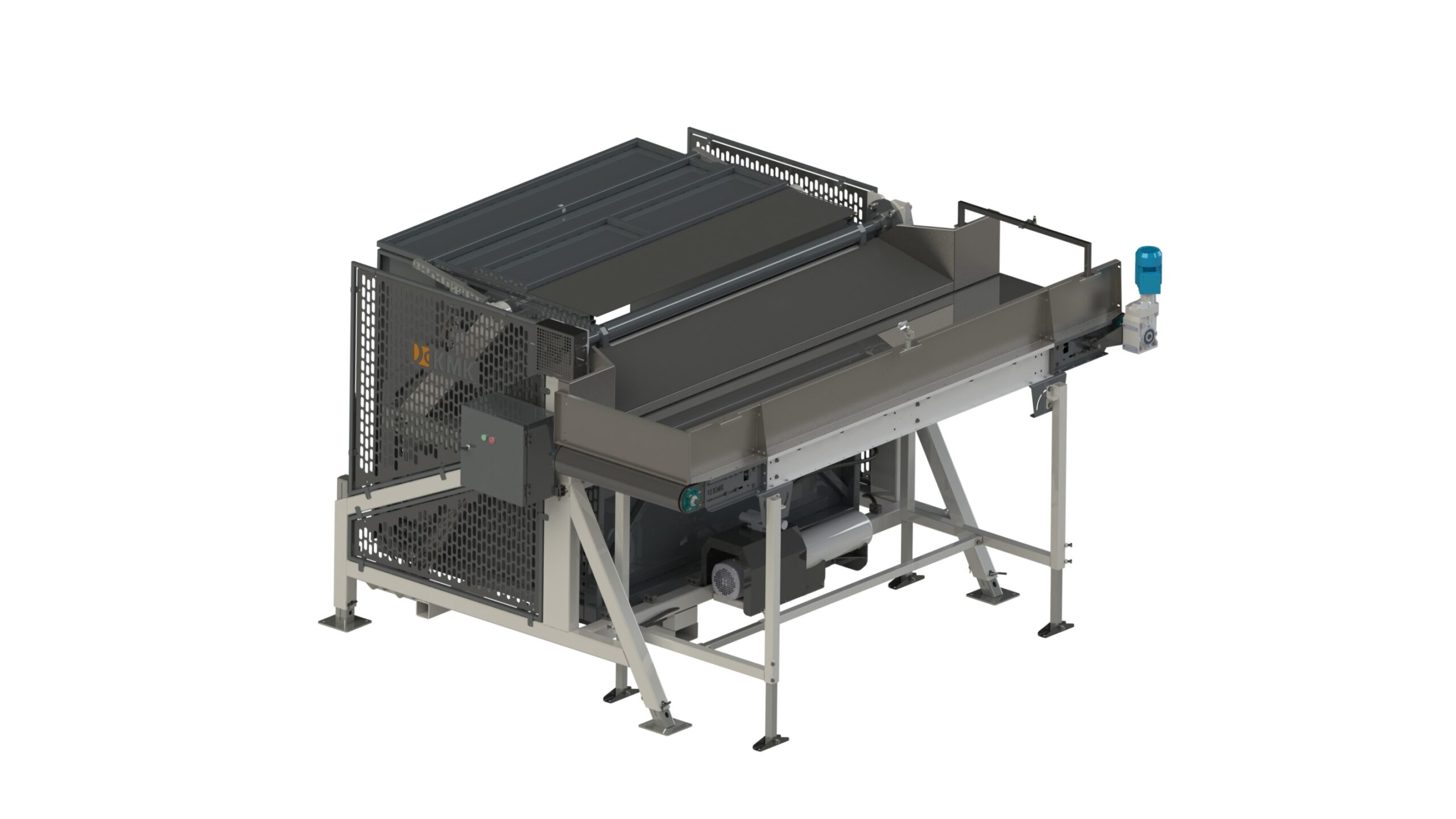

WSD Intelligent Box Tipper and Doser: The All-in-One Intake Solution

Revolutionize the start of your production line with the KMK WSD, an intelligent machine that functions as both a powerful box tipper and a precision dosing dispenser. This advanced, all-in-one system eliminates the need for a separate receiving hopper or bunker, saving valuable floor space and reducing your overall equipment investment while providing an exceptionally consistent product flow.

The Smart Dosing System

The WSD is engineered for true "set it and forget it" operation. The operator simply enters the desired output capacity (e.g., tons per hour) into the advanced touch panel. From there, a sophisticated dual-sensor system takes over:

-

An ultrasonic sensor monitors the product level on the integrated conveyor and automatically adjusts the box's tipping angle to maintain that level.

-

A second sensor further down the conveyor measures the depth of the product and automatically adjusts the conveyor belt's speed.

These two systems work in perfect harmony to guarantee a steady, accurate, and even flow of vegetables to the rest of your line, preventing surges and ensuring optimal efficiency.

Professional-Grade Features for Maximum Performance:

-

2-in-1 Tipper & Doser: A space-saving and cost-effective design that streamlines your entire intake process.

-

Precise Flow Control: The intelligent dual-sensor system delivers a consistent output, measured in tons per hour, for unmatched line efficiency.

-

Controlled Unloading: A hydraulically driven box cover provides an extra layer of control, ensuring a smooth discharge and preventing product spillage.

-

Complete Emptying: A powerful hydraulic mechanism achieves a full 180° tipping angle, ensuring no product is left behind in the box.

-

Operator Efficiency & Safety: Comes standard with a radio remote control, allowing the forklift operator to manage the machine safely from their cab.

-

Flexible Layout Options: The integrated unloading conveyor is available in both longitudinal and crosswise configurations to fit any line layout.

-

Versatile Sizing: The WSD is available in different sizes to handle boxes with widths from 1400 mm up to 2400 mm.

| Technical data: | ||||||

| WSD-14 | WSD-16 | WSD-18 | WSD-20 | WSD-22 | WSD-24 | |

| Max. box width | 1,4 m | 1,6 m | 1,8 m | 2,0 m | 2,2 m | 2,4 m |

| Max. box height | 1,3 m | |||||

| Max. tipping angle | 180° | |||||

| Electrical supply | 400 V | |||||

| Power consumption | 3,5 kW | |||||

Optional equipment:

- Adjustment to central control cabinet